|

|

Our Profile |

Hot In-Place Recycling

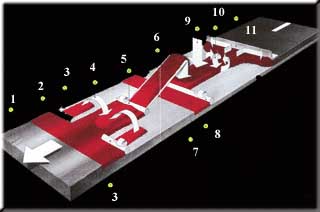

Hot In-Place Asphalt Recycling is able to recycle 100% of existing asphalt to a depth of 50 mm (2.0"). This is accomplished by heating and removing two separate layers of asphalt from the road surface, combining the two layers and relaying it by conventional methods. The result is a low cost, high quality and environmentally friendly surface that can be created quickly with minimal disruption in traffic.

Operating Parameters (please refer to above diagram):

|

||

|

|

Hot In-Place Recycling | |||

|

|

Economic Benefits | |||

|

|

Environmental Benefits | |||

|

|

Links | |||

|

|

Home | |||

|

|

Contact

Us

|